How Can Heat-Resistant Wires Improve Stability in Precision Instruments?

Published:

2025-10-29 13:46:52

Ensure instrument stability with High-Temperature Resistant Cables. Select TL-LINK for proven heat-resistant performance

Precision instruments—used in automotive testing, aerospace systems, laboratory measurement tools, and high-end manufacturing—demand absolute accuracy. Even a minor fluctuation in temperature or voltage can lead to errors or equipment failure. That’s where High-Temperature Resistant Cables come in.

These cables play a crucial role in maintaining reliability, safety, and measurement precision, especially in environments exposed to heat, vibration, and chemical stress. In this blog, we’ll explore how these cables improve performance, reduce maintenance costs, and ensure long-term stability—plus why TL-LINK remains a trusted partner for industrial cable solutions.

The Role of Heat in Precision Instrument Performance

Temperature Instability—A Hidden Threat

When instruments operate near high temperatures—like in engine testing, manufacturing lines, or analytical labs—the electrical conductors and insulation materials are constantly stressed. Regular cables can soften, deform, or lose insulation resistance, resulting in:

Signal distortion

Voltage leakage

Equipment malfunction

Calibration drift

High-Temperature Resistant Cables prevent these problems by maintaining their structural and electrical integrity even in extreme conditions up to +200°C or more. This ensures consistent power or signal transmission, which is vital for precision measurement systems.

How High-Temperature Resistant Cables Enhance Accuracy

1. Stable Signal Transmission

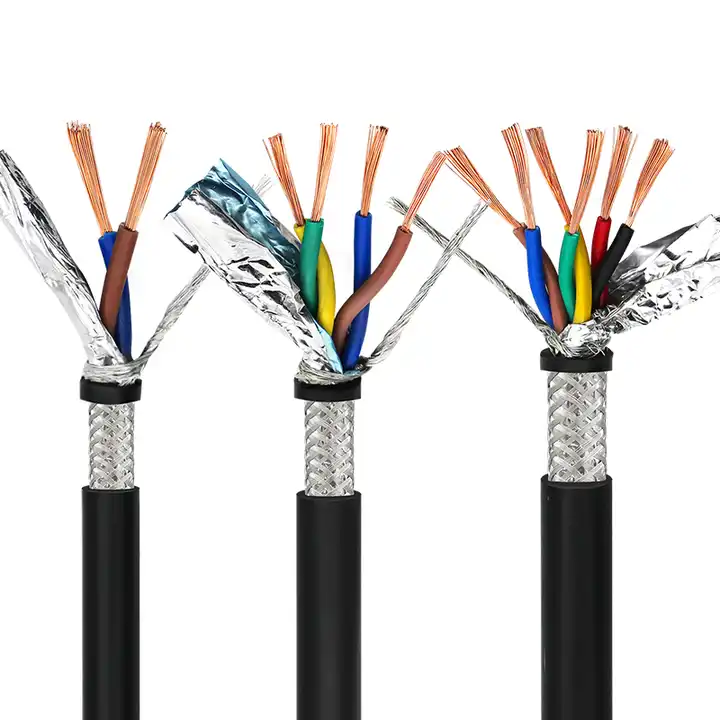

Heat-resistant wires are designed using materials like silicone rubber, PTFE (Teflon), or fiberglass, which maintain low capacitance and minimal signal loss even under thermal stress.

This stability ensures that temperature sensors, flow meters, or microcontrollers receive accurate data in real time—critical for applications in:

Aerospace control systems

Laboratory instruments

Industrial automation devices

2. Reduced Electrical Noise

In precision measurement, even slight electromagnetic interference (EMI) can corrupt readings.

TL-LINK’s High-Temperature Resistant Cables often incorporate braided shielding or foil layers to minimize EMI, ensuring cleaner signals and more reliable results.

3. Extended Equipment Lifespan

Constant exposure to heat accelerates wear and tear on regular wiring. High-temp cables maintain insulation strength and resist oxidation, thereby:

Preventing short circuits

Reducing repair frequency

Extending machine uptime

Where Precision Meets Durability—Industries That Benefit Most

Automotive and EV Manufacturing

From battery management systems to sensor modules, the automotive sector relies on high-temperature cables for reliable data transmission in harsh environments. These cables endure constant vibration, thermal shock, and exposure to chemicals.

Aerospace and Defense

Aircraft and spacecraft systems operate in fluctuating temperatures. High-temp wires ensure fault-free communication and control, even at extreme altitudes or during re-entry.

Laboratory and Analytical Equipment

In labs, instruments such as spectrometers or precision ovens require consistent voltage delivery and low-noise signals—both ensured by High-Temperature Resistant Cables.

Industrial Automation

Robotic arms and CNC systems generate high heat during operation. Durable, flexible, and heat-resistant cables reduce downtime and keep automation processes running efficiently.

Key Features of TL-LINK High-Temperature Resistant Cables

When precision and durability are non-negotiable, TL-LINK stands out with advanced cable engineering. Here’s why industries choose us:

Superior Temperature Range: Designed to perform flawlessly from -20°C to +80°C.

Multiple Insulation Options: Silicone, PTFE, and FEP for different industrial needs.

Flexible Construction: Allows easy routing in compact equipment without signal loss.

Flame-Retardant and Chemical-Resistant: Ideal for demanding manufacturing environments.

RoHS & REACH Certified: Ensuring eco-friendly and safe material compliance.

At TL-LINK, we customize cable solutions to meet exact technical and environmental demands—because no two applications are identical.

Why Choose TL-LINK for Industrial Cable Solutions?

Selecting the right supplier is as important as the cable itself. TL-LINK combines technical expertise with customer-focused service to deliver:

OEM/ODM Manufacturing for bulk and customized needs.

Global Logistics Support for fast delivery across B2B markets.

Strict Quality Assurance, ensuring each cable meets international standards.

Choosing TL-LINK’sHigh-Temperature Resistant Cables means choosing stability, longevity, and precision—all at competitive pricing.

Conclusion

In high-stakes industries, precision is everything. High-Temperature Resistant Cables aren’t just components—they are safeguards that protect measurement integrity, ensure operational stability, and extend equipment lifespan.

Whether you’re a B2B buyer, OEM manufacturer, or industrial designer, investing in reliable heat-resistant wiring today ensures smooth operations tomorrow.

Choose TL-LINK—where performance and reliability meet innovation.

FAQ:

Q1: What materials are used in High-Temperature Resistant Cables?

A1: Common materials include silicone rubber, PTFE, FEP, and fiberglass—all offering superior insulation and heat resistance up to 80°C.

Q2: Can these cables be used in outdoor or high-humidity environments?

A2: Yes. Many TL-LINK cables include moisture-proof and UV-resistant coatings, ideal for outdoor and industrial applications.

Q3: How do I choose the right high-temperature cable for my equipment?

A3: Consider the operating temperature, voltage rating, and flexibility required. TL-LINK’s engineers can help you select or customize the ideal solution.