What Makes Custom High Flexible Shielded Cables Essential for Automation?

Published:

2024-12-10 15:35:55

Custom high flexible shielded cables are designed to meet the demands of automation systems.

The integration of custom high flexible shielded cables plays a critical role in ensuring smooth operations, particularly in robotics and industrial machinery. These specialized cables not only handle complex motion but also protect against electrical interference, making them indispensable in modern automation.

Key Features of Custom High Flexible Shielded Cables

Custom high flexible shielded cables are designed to meet the demands of automation systems. Their unique features include:

High Flexibility

These cables are engineered to withstand repeated bending and twisting, making them ideal for applications involving constant motion, such as robotic arms and conveyor systems.Electromagnetic Interference (EMI) Shielding

The shielding material prevents EMI, ensuring that sensitive equipment operates without disruptions. This is especially crucial for flexible shielded cables for robotics, where precise control is necessary.Durability in Harsh Environments

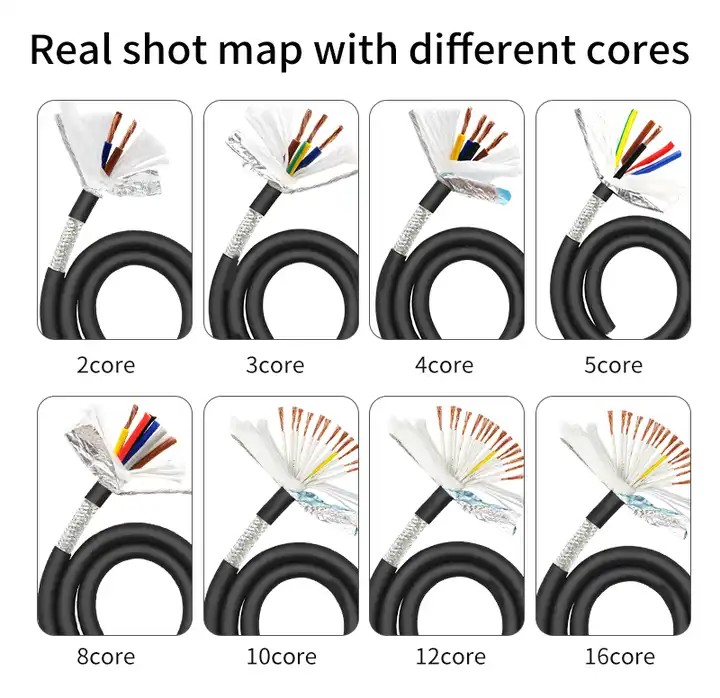

Automation often occurs in challenging conditions, including extreme temperatures, moisture, and exposure to chemicals. Custom shielded cables are built to endure these environments while maintaining performance.Customizable Solutions

Manufacturers can tailor the cable’s length, diameter, and shielding type to meet specific industry requirements, ensuring compatibility with various automation systems.

Applications of High Flexible Shielded Cables in Automation

| Application | Description |

|---|---|

| Robotics | Enable seamless movement and control of robotic arms and automated systems. |

| Industrial Machinery | Provide reliable connections for dynamic parts in machinery. |

| Medical Devices | Ensure precision and safety in equipment requiring high-frequency signals and flexible connections. |

| Data Transmission Systems | Deliver stable and interference-free data transfer in high-motion environments. |

| Automotive Manufacturing | Withstand repetitive motion and harsh conditions in production lines. |

Why Automation Needs Flexible Shielded Cables

Enhanced Performance in Robotics

In robotics, movement precision is critical. Cables must endure constant motion without signal loss, which flexible shielded cables manufacturers ensure by using high-quality shielding materials and flexible designs.Reduction of Downtime

High durable cables minimize wear and tear, reducing maintenance needs and ensuring continuous operation, which is vital in high-speed automation lines.Improved Safety

Customized shielded cables provide insulation and protection, reducing the risk of electrical hazards. This is especially important for systems operating in proximity to human workers.

How to Choose the Right High Flexible Shielded Cables?

To maximize the benefits of these cables, it’s essential to choose a reliable high flexible shielded wire supplier. Consider the following factors:

Material Quality

Ensure that the insulation and shielding materials are robust enough for your operating environment.Flexibility Requirements

Evaluate the bend radius and flexibility of the cables, especially for applications involving repetitive motion.Customization Options

Work with manufacturers who can customize cable specifications to fit your unique automation needs.Certification and Standards

Select cables that meet industry standards for safety, durability, and performance.

TL-LINK: Your Trusted Partner in Custom Shielded Cables

As a leading high flexible shielded wire supplier, TL-LINK specializes in providing high-performance cables tailored to meet the unique needs of automation industries. Whether you need cables for robotics, industrial machinery, or medical devices, we deliver:

- Flexible Shielded Cables for Robotics designed to handle dynamic applications.

- Customized Shielded Cables that meet specific requirements for performance and durability.

- Expertise as one of the most reliable flexible shielded cables manufacturers globally.

Custom high flexible shielded cables are the backbone of modern automation. They enable seamless operation, enhance safety, and ensure the longevity of equipment. Partnering with a trusted manufacturer like TL-LINK ensures that your automation systems are equipped with cables that meet the highest standards of performance and reliability.

FAQ:

Q1: What industries benefit most from custom shielded cables?

A: Industries such as robotics, medical devices, automotive manufacturing, and industrial machinery rely heavily on these cables for precision and durability.

Q2: Why is shielding important in automation cables?

A: Shielding protects against electromagnetic interference (EMI), ensuring stable signal transmission and equipment functionality.

Q3: Can flexible shielded cables withstand harsh environments?

A: Yes, they are designed to perform in extreme conditions, including high temperatures, moisture, and exposure to chemicals.

Q4: How can I customize high flexible shielded cables for my project?

A: Manufacturers like TL-LINK offer tailored solutions, including cable length, shielding type, and material specifications to meet your requirements.

Q5: Why choose TL-LINK for flexible shielded cables?

A: TL-LINK offers industry-leading expertise, high-quality materials, and fully customizable solutions to enhance your automation systems.