How to Test the Performance of an RVVP Shielded Flexible PVC Cable?

Published:

2024-11-19 15:29:09

Discover premium RVVP shielded flexible PVC cable for interference-free performance. High-quality RVVP shielded flexible wire from trusted suppliers.

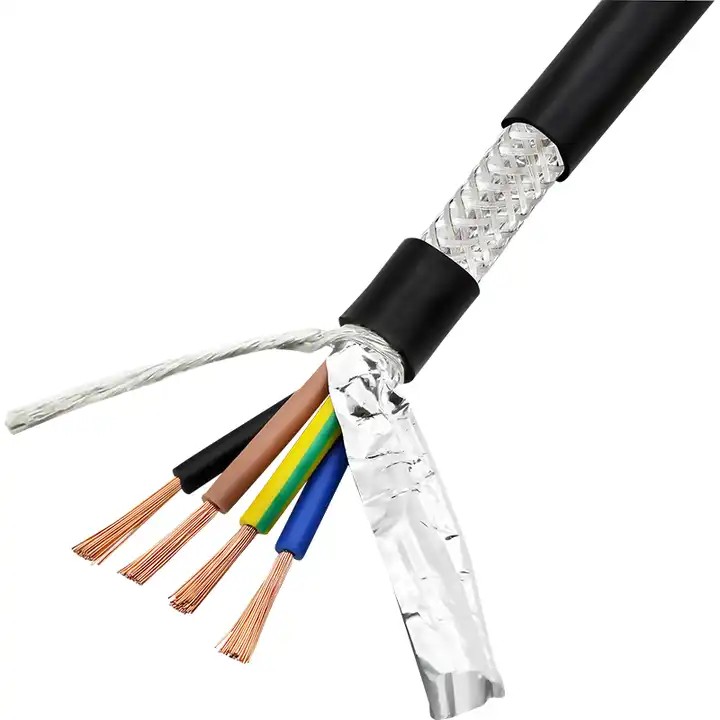

When it comes to reliable signal transmission and robust electrical connections, RVVP shielded flexible PVC cable is a top choice across various industries. Known for its excellent shielding properties and flexibility, this type of cable is ideal for applications where interference protection and ease of installation are critical. To ensure optimal performance and longevity, it’s important to test the quality and functionality of the cable before and after installation. In this article, we’ll explore how to effectively test an RVVP shielded flexible PVC cable, ensuring it meets the highest performance standards set by brands like TL-LINK.

1. Visual Inspection

Before performing any technical tests, start with a thorough visual inspection of the RVVP shielded flexible cable:

· Outer Jacket: Check the PVC jacket for any visible damage, such as cuts, abrasions, or deformation.

· Shielding Integrity: Inspect the shielding layer (usually aluminum foil or braided copper) for uniformity and completeness. Any gaps or damage can compromise the cable’s ability to block interference.

· Connector Quality: Ensure that connectors, if pre-installed, are securely attached and free from defects.

A clean, undamaged cable is crucial for optimal performance during electrical and signal transmission.

2. Conductivity Testing

The core wires in an RVVP shielded flexible wire are responsible for carrying electrical signals. Conductivity testing verifies that the wires have a consistent and low-resistance path for current flow.

Steps for Testing Conductivity:

1. Use a digital multimeter or continuity tester.

2. Connect the probes to both ends of a conductor within the cable.

3. Ensure the resistance is minimal (typically below 1 ohm, depending on the cable length).

Low resistance ensures efficient current flow, while high resistance or open circuits indicate potential damage or defects.

3. Insulation Resistance Test

The PVC insulation of an RVVP shielded flexible PVC cable protects against short circuits and leakage currents. Testing its insulation resistance ensures safety and prevents energy loss.

Steps for Testing Insulation Resistance:

1. Use a megohmmeter (megger) for this test.

2. Apply a specified voltage (as per the cable’s rated voltage) between the core wire and the shield layer.

3. Measure the resistance, which should typically be in the megohm range.

High insulation resistance indicates effective insulation, while low resistance may signify degradation or damage to the PVC jacket.

4. Shielding Effectiveness Measurement

One of the key features of an RVVP shielded flexible cable is its ability to block electromagnetic interference (EMI). To test its shielding effectiveness:

1. Place the cable in an environment with controlled EMI sources.

2. Use a spectrum analyzer or signal tester to measure noise levels within the cable during signal transmission.

3. Compare the results with unshielded or poorly shielded cables to validate the shielding performance.

A well-shielded RVVP flexible wire like those from TL-LINK will exhibit minimal interference, ensuring clean and stable signal transmission.

5. Flexibility and Durability Test

The flexibility of an RVVP shielded flexible wire is vital for installations requiring frequent bending or movement. Conduct the following tests to evaluate flexibility and durability:

· Bend Test: Bend the cable repeatedly at a specified radius to check for cracks, insulation wear, or signal loss.

· Tensile Strength Test: Pull the cable with a calibrated force to verify its strength under tension.

Cables that maintain performance after these tests demonstrate excellent durability and adaptability for various applications.

6. Voltage Drop Test

For electrical applications, voltage drop across the cable is a critical factor. Excessive voltage drop can lead to inefficiencies and signal degradation.

Testing Steps:

1. Connect the cable to a power source with a known voltage.

2. Measure the voltage at the source and at the load end of the cable.

3. Calculate the voltage drop; it should be within acceptable limits for the cable’s specifications.

Low voltage drop confirms that the cable is suitable for delivering power efficiently over its intended length.

7. Real-World Load Testing

After conducting laboratory tests, simulate real-world conditions to verify the cable’s performance under operational stress. For example:

· Test the cable with its intended electrical load or data transmission speed.

· Monitor for heat buildup, signal degradation, or any unusual behavior.

Real-world testing ensures that the RVVP shielded flexible PVC cable will perform reliably in its actual application.

Conclusion:

Testing the performance of an RVVP shielded flexible PVC cable is essential to ensure safety, durability, and optimal functionality. By conducting a combination of visual inspection, electrical tests, and real-world simulations, you can verify that the cable meets high-quality standards, such as those maintained by TL-LINK. Proper testing not only ensures reliability but also enhances the lifespan of the cable in demanding applications.

FAQ:

1. What is an RVVP shielded flexible PVC cable?

An RVVP shielded flexible PVC cable is a flexible cable with a shielding layer and PVC insulation, designed for interference-free electrical and signal transmission.

2. Why is shielding important in RVVP flexible cables?

Shielding in RVVP shielded flexible cables reduces electromagnetic interference (EMI), ensuring stable and reliable signal transmission.

3. How can I identify a high-quality RVVP shielded flexible wire?

Look for consistent shielding, low resistance, high insulation resistance, and certifications from trusted manufacturers like TL-LINK.

4. Can RVVP shielded flexible PVC cables be used outdoors?

Yes, depending on the cable’s specific rating and protective layers. Verify the product specifications to ensure it’s suitable for outdoor use.