How to Maintain Multi-Core PVC Insulated Flexible Cables?

Published:

2024-10-29 16:06:19

Maintaining multi-core PVC insulated flexible cables involves routine inspections, secure connections, proper storage, and avoiding exposure to extreme conditions.

Multi-core PVC insulated flexible cables are crucial in various industrial and commercial applications, offering reliability and durability in high-stress environments. However, to ensure long-term performance, maintaining these cables is essential. Proper maintenance reduces downtime, extends the cable’s lifespan, and ensures safe, efficient operations. In this article, we’ll cover the best practices for maintaining multi-core PVC insulated flexible cables, focusing on their unique needs and incorporating relevant industry standards.

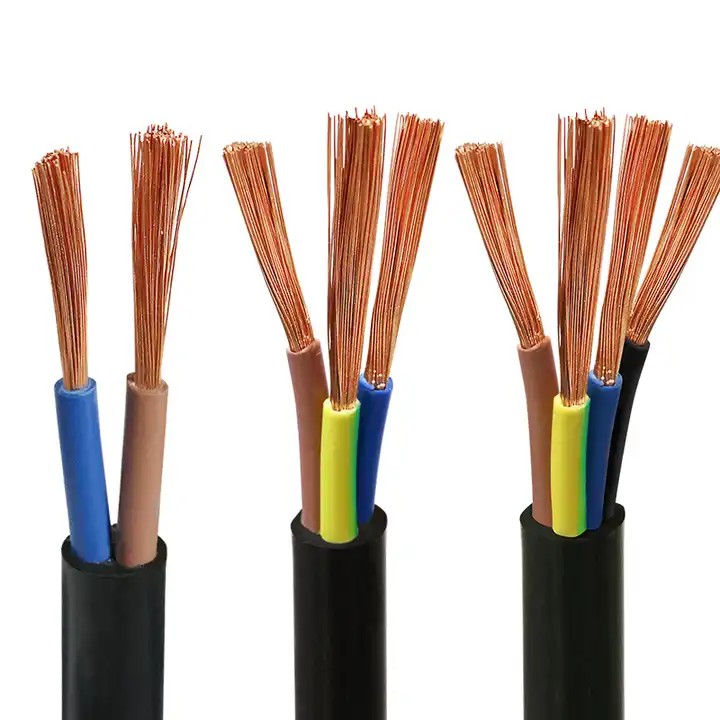

Understanding Multi-Core PVC Insulated Flexible Cables

Multi-core PVC insulated flexible cables consist of multiple insulated conductors wrapped in a durable outer sheath. Their PVC insulation makes them resistant to chemicals, moisture, and abrasion, making them ideal for industrial and commercial environments where conditions may be harsh. Proper maintenance not only helps avoid common wear and tear issues but also protects against potential electrical hazards, making it essential for workplace safety.

Key Maintenance Practices for Multi-Core PVC Insulated Flexible Cables

1. Regular Visual Inspections

Regular visual inspections are the foundation of cable maintenance. Check for any signs of wear, such as cracking, abrasion, or discoloration in the PVC insulation. This can help identify early issues before they become serious problems.

Inspecting insulation integrity: Any damage to the outer insulation layer can expose internal wires, leading to electrical shorts or reduced cable efficiency.

Identifying strain: Multi-core cables, especially flexible ones, may show signs of strain near connectors or bend points. If frequent bending is part of the cable’s application, ensure that there is no excessive bending or coiling, which can damage the cable over time.

2. Testing Cable Continuity

To ensure that multi-core PVC insulated flexible cables remain fully functional, regularly test their electrical continuity. This will help identify internal breaks or faults that may not be visible. By checking continuity, you can determine if any of the internal cores have disconnected or have excessive resistance, which can compromise the cable’s performance.

3. Cleaning and Dust Removal

Dust and debris can accumulate on cables in industrial environments. Over time, this buildup can weaken the PVC insulation, especially if it becomes damp or is exposed to chemical substances.

Using appropriate cleaning agents: Avoid harsh chemicals that can degrade the PVC insulation. Instead, use mild detergents or dedicated cable cleaning products.

Removing dust: Use a soft, dry cloth to remove dust or a compressed air canister to blow away debris. This will maintain cable flexibility and reduce abrasion.

4. Avoiding Over-Bending and Kinking

Although multi-core PVC insulated flexible cables are designed to withstand bending, excessive or sharp bends can weaken the cable over time. When installing or handling these cables:

Follow the recommended bend radius: Each cable has a specified minimum bend radius to ensure long-term flexibility and durability. Exceeding this radius can cause the internal conductors to break or insulation to crack.

Use cable guides: If the cable moves during operation, using guides can prevent excessive bending and improve cable lifespan.

5. Temperature Management

PVC insulation can tolerate a range of temperatures but is sensitive to extreme heat. To maintain your cables:

Avoid excessive heat exposure: Ensure cables aren’t in contact with hot surfaces or exposed to extreme temperatures, as this can cause the PVC to degrade over time.

Check insulation for signs of heat stress: Heat stress on multi-core PVC insulated flexible cables can lead to cracks or stiffness in the insulation layer, reducing flexibility and increasing the risk of electrical shorts.

6. Securing Connections

Loose or poorly connected cables can lead to signal loss or potential safety hazards. Secure all cable connections, especially in industrial settings where vibrations and movement may loosen them over time.

Use strain relief fittings: When connecting multi-core PVC insulated flexible cables, use strain relief fittings to prevent tugging or stress on the connectors.

Check for corrosion at connection points: In humid or outdoor environments, corrosion can form on metal connectors. Regularly clean these areas to ensure a stable connection.

7. Storage Best Practices

For cables not in use, proper storage is essential to prevent kinks, strain, or other damage. When storing multi-core PVC insulated flexible cables:

Use appropriate cable reels: Wind cables loosely on reels, ensuring there’s no excessive tension. Avoid tight wrapping, as it can cause permanent bends.

Keep in a dry, clean environment: Moisture or chemical exposure during storage can degrade the PVC insulation. Ideally, store cables in a controlled environment to maintain their flexibility and durability.

Choosing a Reliable Supplier

Selecting a reputable supplier is an important first step to ensure your cables are of the highest quality and meet the demands of your environment. Working with a supplier experienced in multi-core PVC insulated flexible cables will give you access to cables that have been rigorously tested for durability and flexibility. A reliable supplier can also provide additional guidance on specific maintenance needs based on the cable's application.

Benefits of Proper Maintenance for Multi-Core PVC Insulated Flexible Cables

Extended Lifespan: Regular maintenance significantly extends the life of multi-core PVC insulated flexible cables, making them a more economical choice over time.

Improved Safety: Well-maintained cables reduce the risk of electrical hazards, ensuring a safer work environment.

Cost Savings: Preventing premature failure reduces replacement costs and minimizes downtime for repairs.

Optimized Performance: Consistent cable performance ensures that equipment and systems run smoothly, with less risk of data loss or signal interference.

Maintaining multi-core PVC insulated flexible cables involves routine inspections, secure connections, proper storage, and avoiding exposure to extreme conditions. With these practices, you can ensure the cables remain effective, safe, and durable over their lifespan. Regular maintenance also brings long-term cost benefits, especially in demanding industrial and commercial settings. Working with a reliable flexible coaxial cable supplier ensures that you get high-quality cables designed to withstand industrial challenges, making multi-core PVC insulated flexible cables a wise investment for any application.