How does the shielding affect the flexibility of shielded wire?

Published:

2024-04-08 21:54:58

we will explore how wire shielding affects the flexibility of shielded electrical wire, highlighting the factors involved and the implications for different applications.

Shielded electrical wire plays a crucial role in various industries and applications, providing protection against electromagnetic interference (EMI) and ensuring reliable signal transmission. One aspect that significantly influences the performance and usability of shielded wire is its flexibility. In this article, we will explore how wire shielding affects the flexibility of shielded electrical wire, highlighting the factors involved and the implications for different applications.

Understanding Wire Shielding:

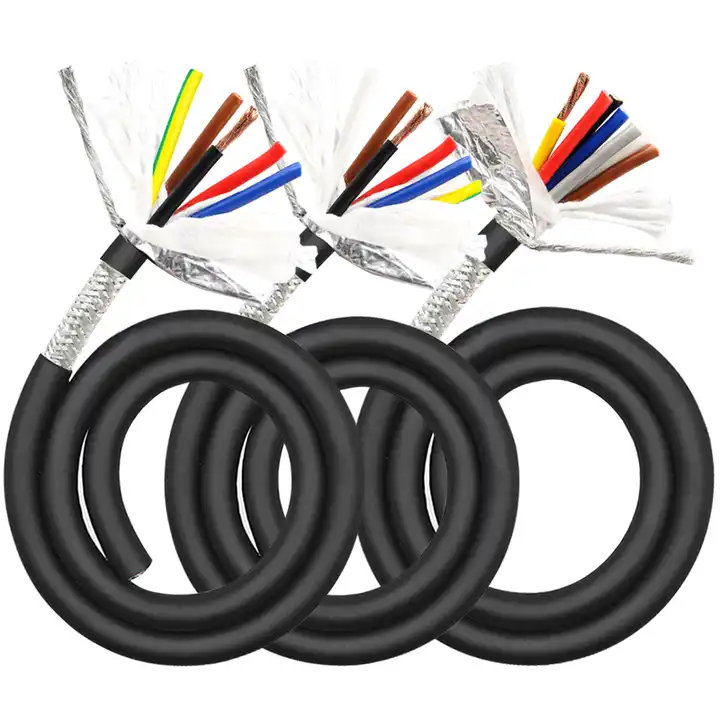

Wire shielding refers to the process of adding an additional layer of shielding material around the conductors of electrical wire to protect against EMI and radio frequency interference (RFI). This shielding layer, typically made of metal such as aluminum or copper, forms a protective barrier that absorbs and reflects electromagnetic waves, preventing external interference from affecting signal integrity. While shielding enhances the performance and reliability of electrical wire, it can also impact its flexibility depending on various factors.

Factors Affecting Flexibility:

1. Shielding Material: The type and thickness of the shielding material used can significantly influence the flexibility of shielded electrical wire. Heavy or rigid shielding materials may reduce flexibility, making the wire less pliable and more challenging to bend or maneuver. Conversely, lightweight and flexible shielding materials can help maintain the wire's flexibility while still providing adequate EMI protection.

2. Shielding Design: The design of the shielding layer, including its configuration and construction, can affect the flexibility of shielded electrical wire. For example, a braided shielding design, consisting of interwoven strands of shielding material, may offer greater flexibility compared to a solid or foil shielding design. The flexibility of shielded wire can also be influenced by the number of shielding layers and their arrangement around the conductors.

3. Insulation Thickness: The thickness of the insulation layer surrounding the conductors can impact the overall flexibility of shielded electrical wire. Thicker insulation may add bulk and rigidity to the wire, reducing flexibility, especially in applications where tight bending radii are required. However, thinner insulation materials with adequate mechanical strength can help maintain flexibility while still providing sufficient insulation and EMI protection.

4. Conductor Size and Configuration: The size and configuration of the conductors within the shielded wire assembly can also affect flexibility. Larger conductors or complex conductor configurations may require thicker insulation and shielding layers, potentially limiting flexibility. Conversely, smaller conductors and simpler configurations may allow for thinner insulation and shielding layers, improving flexibility without compromising performance.

Implications for Different Applications:

1. Industrial Automation: In industrial automation applications where flexible wiring is essential for routing through machinery and equipment, shielded electrical wire with lightweight and flexible shielding materials is preferred. Flexible shielded wire allows for easier installation and maintenance, ensuring reliable signal transmission in dynamic environments.

2. Telecommunications: In telecommunications systems where high-frequency signals are transmitted over long distances, shielded electrical wire with flexible shielding designs is essential to minimize signal distortion and ensure data integrity. Flexible shielded wire allows for easy routing and termination in telecommunications infrastructure, supporting seamless communication networks.

3. Audio/Video Systems: In audio/video systems where noise and interference can degrade signal quality, shielded electrical wire with flexible shielding materials and configurations is critical for maintaining audio and video fidelity. Flexible shielded wire enables easy installation and connection of audio/video components, delivering immersive multimedia experiences.

The flexibility of shielded electrical wire is influenced by various factors, including the type of shielding material, shielding design, insulation thickness, and conductor size and configuration. While shielding enhances EMI protection and signal integrity, it can also impact the flexibility of the wire, especially in applications where flexibility is crucial for installation and maintenance. By carefully selecting flexible shielded wire with optimized shielding materials and designs, manufacturers and users can ensure reliable performance and ease of use in diverse applications across industries such as industrial automation, telecommunications, and audio/video systems.